What kind of shirts wont shrink? What type of material will allow my body to breathe? Which is the softest material?These are all questions that come about when deciding what type of t-shirts to order. There are plenty of different t-shirts out on the market – some made of cotton and others of polyester, but which is the best? This really all depends on the purpose of the shirts.

If the shirts would be used for promotional purposes, chances are you would want to give them the cheapest shirts possible. This way your still able to get your message across with spending the least amount of money as possible. For a promotional job I would suggest using 100% Cotton 5-6 oz t-shirts, something like the Delta 11730 or Gildan 5000. These shirts are affordable in price, come in various sizes and somewhat long lasting. The downside with these shirts is how much they shrink when put through wash cycles. But then again what the heck, these shirts will most probably be worn once and then used as Pajamas.

If the shirts would be used for promotional purposes, chances are you would want to give them the cheapest shirts possible. This way your still able to get your message across with spending the least amount of money as possible. For a promotional job I would suggest using 100% Cotton 5-6 oz t-shirts, something like the Delta 11730 or Gildan 5000. These shirts are affordable in price, come in various sizes and somewhat long lasting. The downside with these shirts is how much they shrink when put through wash cycles. But then again what the heck, these shirts will most probably be worn once and then used as Pajamas.

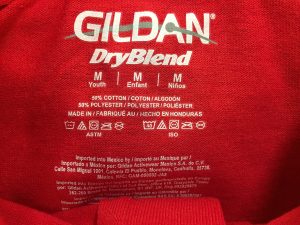

Another common used t-shirt material would be a 50/50 blend, that is 50% cotton and 50% polyester. These types of shirts are generally ordered by sports organizations and contractors because the fabric allows the body to breathe. The upside of these shirts is that they shrink less than the cotton tees – since they are made of up 50% synthetic material (polyester), they tend to shrink less than the basic t-shirts. Some sports teams and organizations even go for 100% Polyester moisture wicking shirts, which keep the body cool and absorb the persons sweat.

Another common used t-shirt material would be a 50/50 blend, that is 50% cotton and 50% polyester. These types of shirts are generally ordered by sports organizations and contractors because the fabric allows the body to breathe. The upside of these shirts is that they shrink less than the cotton tees – since they are made of up 50% synthetic material (polyester), they tend to shrink less than the basic t-shirts. Some sports teams and organizations even go for 100% Polyester moisture wicking shirts, which keep the body cool and absorb the persons sweat.

Finally, a little bit more expensive and my personal favorite fabric, is the Triblend material. This is made up of 3 materials – cotton, polyester and rayon, hence the name TRI blend. Most of these feel silk smooth on the body, I suppose this is due to the rayon material and the combed finish. These are a bit trickier to print, since each of the material has a different burning temperature and ink curing temperature. In order to print the printer needs to find a “sweet spot” where the ink cures, but the garments don’t burn. Another thing to mention is the garments most often look heather, this is the old vintage look that you see on shirts.

Finally, a little bit more expensive and my personal favorite fabric, is the Triblend material. This is made up of 3 materials – cotton, polyester and rayon, hence the name TRI blend. Most of these feel silk smooth on the body, I suppose this is due to the rayon material and the combed finish. These are a bit trickier to print, since each of the material has a different burning temperature and ink curing temperature. In order to print the printer needs to find a “sweet spot” where the ink cures, but the garments don’t burn. Another thing to mention is the garments most often look heather, this is the old vintage look that you see on shirts.

Deciding on which fabric should be pretty simple, but your local screen printer should always be able to point you in the right direction and make suggestions for you.

Are you up for starting your own line of T-Shirts? Possibly hoodies and other items? Do you think you have what it takes? It seems all simple and easy from the outside, but going into the new venture without a too much of a clue of what’s going on might really hurt your pockets.

Are you up for starting your own line of T-Shirts? Possibly hoodies and other items? Do you think you have what it takes? It seems all simple and easy from the outside, but going into the new venture without a too much of a clue of what’s going on might really hurt your pockets. Starting a clothing line consists of a few different steps. To begin, you have to develop art, or a product that is in demand and customers would be willing to buy. For example, coming up with artwork such as the name brand of your line and printing them on basic tee’s will probably not be in high demand. This is because no one knowns who your are and what your brand is, face it your brand is not famous yet. The better way to approach is to follow the trend and give people what they want, like hemmed bottom shirts with skull prints along the front. Or better yet, follow celebrities on their Instagram and Twitter account, that will surely give you a lot of ideas. I have found that for your line, 252 Apparel, the best selling items are shirts the ones thats are based off of Kanye West. He is seen wearing Metallica shirts with bleach stains on them, so we design Metallica style t-shirts and add them to our line.

Starting a clothing line consists of a few different steps. To begin, you have to develop art, or a product that is in demand and customers would be willing to buy. For example, coming up with artwork such as the name brand of your line and printing them on basic tee’s will probably not be in high demand. This is because no one knowns who your are and what your brand is, face it your brand is not famous yet. The better way to approach is to follow the trend and give people what they want, like hemmed bottom shirts with skull prints along the front. Or better yet, follow celebrities on their Instagram and Twitter account, that will surely give you a lot of ideas. I have found that for your line, 252 Apparel, the best selling items are shirts the ones thats are based off of Kanye West. He is seen wearing Metallica shirts with bleach stains on them, so we design Metallica style t-shirts and add them to our line. Curing inks is the process at which the plastisol ink, made of of PVC and plasticizer, is chemically bonded to the natural garment fibers. This process is also sometimes called fusion. The way to to cure inks is generally the same on almost all types of plastisol inks, heat the ink up (on all layers) to about 325-350 degrees Fahrenheit using a conveyor dryer. At this temperature a chemical reaction occurs which fuses, or bonds the ink into the fibers of the garments and permanently secures the ink onto the garments. Once this chemical reaction takes place and the ink is considered “cured” it would be nearly impossible for the ink to comes off in the wash, peel off or scratched off the shirt.

Curing inks is the process at which the plastisol ink, made of of PVC and plasticizer, is chemically bonded to the natural garment fibers. This process is also sometimes called fusion. The way to to cure inks is generally the same on almost all types of plastisol inks, heat the ink up (on all layers) to about 325-350 degrees Fahrenheit using a conveyor dryer. At this temperature a chemical reaction occurs which fuses, or bonds the ink into the fibers of the garments and permanently secures the ink onto the garments. Once this chemical reaction takes place and the ink is considered “cured” it would be nearly impossible for the ink to comes off in the wash, peel off or scratched off the shirt. There are two major tests which most screen printers use in order to determine if plastisol ink is cured. The first and most common method used is what screen printers call the “stretch test”. The stretch test consists of the print-master running the shirt through the conveyor dryer and let them cool off for a bit. Once the shirt is cooled off the print-master stretches the fabric just enough so that the ink can stretch as well. If the ink cracks more than 20% it means that the ink is not cured and most defiantly will come off in the washing machine.

There are two major tests which most screen printers use in order to determine if plastisol ink is cured. The first and most common method used is what screen printers call the “stretch test”. The stretch test consists of the print-master running the shirt through the conveyor dryer and let them cool off for a bit. Once the shirt is cooled off the print-master stretches the fabric just enough so that the ink can stretch as well. If the ink cracks more than 20% it means that the ink is not cured and most defiantly will come off in the washing machine. Whether you are ordering

Whether you are ordering